Introduction:

India is generating about 3.5 million tons of plastic waste annually and the per capita plastic

waste generation has almost doubled over the last five years and about 60% of the plastic waste

has been recycled annually in India. Plastic is made up of various harmful and toxic chemicals

thus it poses a serious environmental threat to modern society. As a result, if not properly

managed or processed it will pollute land, air and water. Plastic Debris affects at least 267

species worldwide 86% of sea turtles species, 44% of all seabird and 43% of marine mammal

species. India has been ranked as the 12th among the countries for mismanagement of plastics.

Therefore recycling and reprocessing of Plastic waste has become the urgency to overcome this

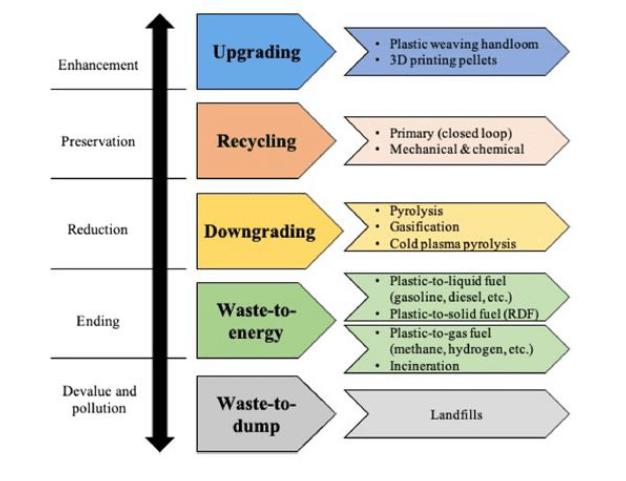

problem and mismanagement. Recycling and reprocessing of Plastic waste involves 5 types of

processes based on the quality of the product manufactured upon recycling namely upgrading,

recycling (open or closed loop), downgrading, waste-to-energy plants, and dumpsites or

landfilling. Usually, the PW is converted into lower-quality products such as pellets or granules,

or flakes which are further utilized in the production of various finished products such as boards,

pots, mats, and furniture (Centre for Science and Environment (CSE) 2021).

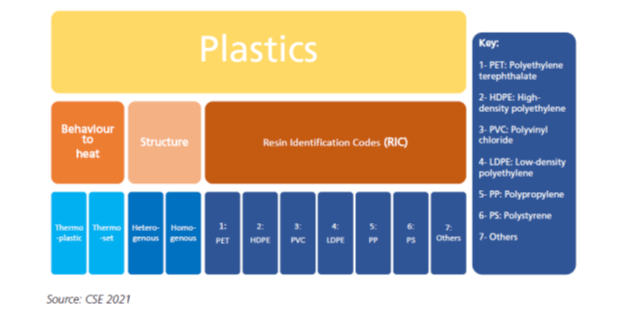

1. Classification of plastics

| Plastic | Characteristics |

| Polyester (EPS) | Lightweight, foamed and energy absorbing plastic |

| Low Density Polyethylene (LDPE) | Milky white, soft and flexible plastic |

| High Density Polyethylene (HDPE) | Relatively of high grade and used in white |

| Polystyrene (PS) | Polystyrene (PS) Stiff but brittle plastic with clear look and glossy |

| Plasticized Polyvinyl Chloride (PPVC) | Clear type with flexibility |

| Polypropylene (PP) | Hard, but flexible plastic |

| Unplasticized Polyvinyl Chloride (UPVC) | Clear type, hard stiff plastic |

| Polyethylene Terephthalate (PET) | Hard plastic suitable for fibre production |

Table.1 Variety and characteristics of plastic

Plastic Recycling Technologies and their applicability to India

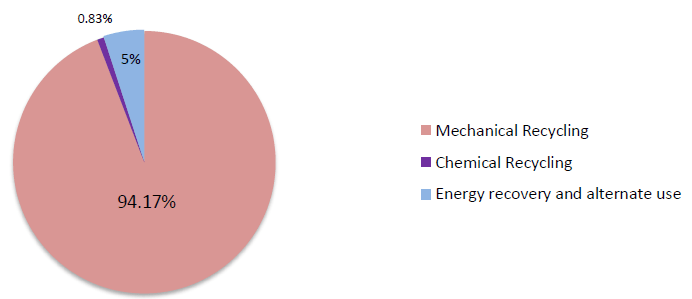

From waste to material recovery, PW recycling can broadly be categorized into mechanical

recycling, chemical recycling, biological recycling, and energy recovery (Al-Salemet al. 2017).

Primary Recycling is most preferable type of recycling because of its contamination free feature

which facilitates a less number of operating units resulting in the optimal amount of consumption

of energy supply and resources which is further followed by secondary recycling (mechanical

recycling) for recycling PW (CSE 2021). However, processing difficulties and the quality of

recyclates are the main drivers for seeking alternative approaches (Ragaert et al. 2017).

Comparatively, tertiary recycling or chemical/feedstock recycling is a less favored alternative

because of high production and operational costs, as well as the lack of scalable commercial

technology in India whereas quaternary recycling which involves energy recovery, energy from

waste, or valorization of PW, is least preferred due to uncertainty around propriety and

prominence of the technology, and the negative potential to convert land-based pollution to water

and air pollution, but anyhow more preferable than dumping into the landfill (Satapathy 2017;

CSE 2021). Figure 2 shows the categorization of the recycling process of PW.

Fig.3 Plastic waste flow and recycling categorization (Modified from FICCI 2016; Sikdar et al.

2020; Tong et al. 2020)

2.1 Recycling technologies

2.1.1 Mechanical Recycling

Mechanical recycling involves physical processes (or treatments) that convert PW into secondary

plastic materials. It is a multistep process typically involving collection, sorting, and heat

treatment with reforming, re-compounding with activities, and extruding operations to produce

recycled material that can substitute for virgin polymer (Ragaert et al. 2017; Faraca and Astrup

2019). It‘s able to handle single polymer plastis only such as PVC, PET, PP & PS. There are

various key approaches to sorting and separating PW for MR, including zig-zag separator (also

known as an air classifier), air tabling, ballistic separator, dry and wet gravity separation (or sinkfloat

tank), froth flotation, and electrostatic separation (or triboelectric separation). There are also

some newer sensor-based separation technologies available for PW which include plastic color

sorting and near-infrared (NIR) (Ministry of Housing & Urban Affairs (MoHUA) 2019). After

the collection process they are melted down directly and molded into new shapes or are regranulated

and these granules are reused to in the manufacturing of plastic products.

2.1.2 Chemical Recycling

Chemical recycling, tertiary recycling, or feedstock recycling refers to the transformation of

polymers into simple chemical structures (smaller constituent molecules) which can be utilized

in a diverse range of industrial applications and/or the production of petrochemicals and plastics

(Bhagat et al. 2016; Jyothsna and Chakradhar 2020). Pyrolysis, hydrogenation, and gasification

are some of the chemical recycling processes (Singh and Devi 2019). This type of recycling is

used in waste to oil plants (Termed as WtO by CPCB)

2.1.3 Quaternary Recycling – Energy Recovery

Energy recovery is a valuable alternative for the plastics that can‘t be sustainably recycled such

plastics can‘t be recycled in an eco-efficient manner because of few factors are:

The amount, cleanliness and composition of the collected waste.

Available technologies for sorting.

Market driven requirements on quality and standards for recycled material that may limit

the appropriateness of plastic recycling.

For these plastics, energy recovery is the most resource-efficient solution available. In India,

most of the plastic waste treated using this method is co-processed in cement plants or sent to

WtE plants to be used as an alternative fuel in the incineration process.

2.1.4 Alternate Use

Alternate use refers to use plastic in some other way and not using technologies discussed above.

One of the best example of alternate use of plastics in bitumen road making. This process,

however, has its limitations in terms of feedstock-this process can‘t take black plastic because of

its repeated recycling and less binding properties and PVC can‘t be used due to presence of

chlorine which can release dioxin in case of high temperature. More research is needed to

understand the long-term effects of plastic being used for alternate purposes in various set-ups to

recognize and address questions like leaching, environmental degradation potential, microplastic

forming potential and other effects on human health.

Graph 1 Percentage distribution of recycling options

3 Challenges faced by recyclers

- The challenges associated with plastic waste and recycling are numerous, and they can be found at all levels, including classification, quantification, identification of sources of plastic waste, fates of lastic waste and disposal options, recycling as a whole, and finally the current GST framework.

- The RIC codes are the most extensively accepted and recognized for classification. However, most of us confuse them as a promise that the plastic will be recycled. Moreover, the resin codes can help us identify the type of resin that was used for making the plastic, but it is almost impossible to establish if a plastic product has been made using virgin material, recycled material, or the so-called compostable and biodegradable plastics. Consumers have to heavily rely on the message communicated to them by producers and brand owners through their packaging, and there is no way to verify the claims made by them in terms of the kind of plastic they are using

- Quantifying plastic trash is an even more difficult task. This topic should take precedence until and unless we have a “realistic” number on which all parties can agree. The current scenario and available records merely show how different government organisations have issued inconsistent numbers on plastic garbage output, and we are nothing near to the actual figure.

- The informal sector is the only reason why we have not drowned in our own waste. While they do most of the work and make it possible to bring everything back into the value chain, they have not been recognized as an institution/ organization and that makes them all the more vulnerable and prevents them from having the right to bargain. The PWM Rules, 2016 have also recognized the waste-picker but not the entire sector as a whole. The losses that the informal sector has had to suffer because of GST have also been highlighted time and again. While plastic waste channelized for recycling is subject to 5 per cent GST, non-recyclable plastic waste which is sent to WtE plants and cement plants for co-processing is procured by these plants free of cost and is delivered to their doorstep.

- The quality of plastics collected is, usually, inconsistent and contaminated leading to lower value items.

- Many plastic recycling companies have insufficient standardization, industrialization and operational excellence in their operations. This is largely due to the nature of the sector, which is characterized by small companies, with limited experience in the professional plastics industry.

- In reality, only a small percentage of ‗recyclable’ used plastic is recycled back into the things for which it was created, even in the case of most easily recyclable plastic such as PET and HDPE. hallenges come due to colorants, additives, and fillers used in the production of plastic. Contamination from consumer use, and yield losses during the recycling process.

- Even if plastic were recycled despite all the barriers, each cycle of the recycling process shortens the length of polymer chains, resulting in quality loss and, eventually, the need to dispose of the material. Lower-grade plastic waste, including post-consumer and multilayered plastic packaging is particularly difficult to separate and process.

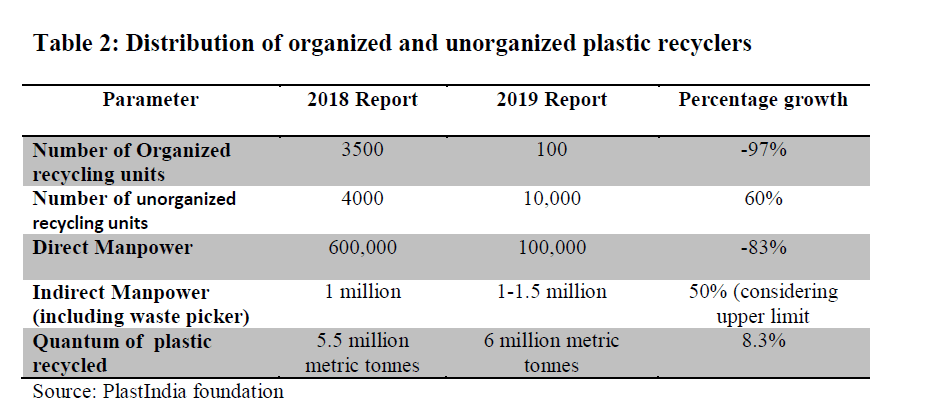

4. Statistics

India is generating about 3.5 million tons of plastic waste annually and the per capita plastic

waste generation has almost doubled over the last five years and about 60% of the plastic waste

has been recycled annually in India. While the amount of plastic waste that is being recycled in

the country matches PlastIndia‘s claim of 60 per cent; according 20 to MoHUA, 70 per cent of

this is recycled in registered or organized facilities which have declined by 97 per cent in a year

(2018–19), 20 per cent is recycled by unorganized sector which has increased by 60 per cent and

the remaining 10 per cent is recycled at home—which means using the plastic waste for alternate

use in a domestic setup.

5. How EcoEx can help to address the above challenges

5.1. Organizing the Unorganized Plastic Recycling Industry – Achieving the Essence of

EPR policy

- EcoEx recognised the need to bring the unorganized recycling sector into the organised segment by informing them of the additional financial benefits they may obtain by selling PCC directly to a pool of PIBOs on our digital marketplace. As a result, the recycling sector can be streamlined.

- Extended Producer Responsibility (EPR) was formed to encourage plastic makers to accept responsibility for recycling the waste they create by incentivizing recyclers to enhance recycling apacity and, as a result, contribute to the country’s recycling infrastructure. Ecoex gives recyclers more power by allowing them to trade directly with PIBOs.

5.2 Educating the Stakeholders

Many PIBOs and recyclers are completely unaware of the EPR policy. Ecoex contributes to

raising awareness by teaching both PIBOs and recyclers about the importance of ethically

offsetting their EPR targets. Ecoex believes that every metric tonne of plastic trash in the

environment should be disposed of ethically, and we are working to educate all stakeholders in

the value chain.

5.3. Lesser plastics into oceans

- The more plastic that is collected and recycled, the less plastic will end up in rivers and oceans, disrupting marine life. Ecoex’s pro-recycling stance ensures that the maximum amount of plastic is removed from the environment.

- Plastic garbage is now flooding the world’s oceans at an alarming rate. The absence of recycling infrastructure. By incentivizing recycling, Ecoex ensures that an increasing amount of post-consumer plastic trash is collected and recovered. This, in turn, aids in the conservation of marine life by reducing the amount of plastic poured into oceans.

5.4. Plastic Credit certificate.

PIBOs can now fulfil their Plastic EPR obligations directly through Recyclers/End of Life

Processors using ECOEX’s digital marketplace. A PCC guarantees that plastic garbage is

ethically collected, transported, and disposed of while also ensuring that the monetary benefit is

realised by the unprivileged recycling sector.

In a plastic credit model, a manufacturer is not obligated to recycle their own packaging but must

verify that an equivalent amount of packaging trash has been recovered and recycled to meet

their duty. Producers, on the other hand, are required to get proof of recycling or recovery

[PLASTIC CREDIT] from appropriately accredited processors [recyclers, W2E plant operators,

cement co-processors, users of plastic in road] or exporters. Producers can exchange credits with

processors who have been officially accredited for this purpose, as well as by registering on the

EPR portal.

Conclusion

Our main goal with this project was to create awareness of how recycling can help the

environment by reducing pollution and greenhouse emissions; which at the same time is

affecting the whole world, and how we can make a difference if we start recycling efficiently.

We also wanted to make people aware of how recycling can make an impact in the world by

decreasing global warming, decreasing deforestation, and reducing the amount of toxic

chemicals that go into the landfills and pollute the soil and lead to degradation of land.

The circular economy is a regenerative paradigm that necessitates the involvement of responsible

stakeholders. There should be continuous interaction among stakeholders to share current

practices dealing with PW as part of the plastic economy. It was found that there was incomplete

and indistinct reporting on PW generation from individual states. Information exchange via

technology application should eventually be an integral part of the PW management value chain.

Thus, generation estimation is an essential task to set targets for resource recovery and recycling,

which connects the ―global commitment‖ element of the circular plastic economy and waste

minimization. Being part of the global commitment to ―reducing, circulating and innovating‖

under the ―plastic pact,‖ a national target could be set and a mechanism is developed.

References:

- Indian Plastics Industry Report, PlastIndia foundation, 2019 Accessed at https://

www.plastindia.org/plastic-industry-status-report.php - Siddharth Ghanshyam Singh 2021. Plastic Recycling: Decoded. Centre for Science and

Environment, New Delhi. - Annual Report 2019-20 on Implementation of Plastic Waste Management Rules, 2016

- pri_plasticslandscape_challengesandpossiblesolutions_743997

- International Journal of Environmental Science and Technology

https://doi.org/10.1007/s13762-022-04079-x - https://www.circulareconomyasia.org/mechanical-recycling/

- https://www.ncbi.nlm.nih.gov/pmc/articles/PMC2873020/

- CPCB Annual Report 2019–2020 (2021). Retrieved from https:// cpcb. nic. in/ uploa ds/

plast icwas te/ Annual_ Report_ 2019- 20_ PWM. Pdf - Ministry of Housing & Urban Affairs (MOHUA) (2019) PW management issues,

solutions & case studies. Retrieved from http:// 164. 100. 228. 143: 8080/ sbm/ conte nt/

write readd ata/ SBM% 20Pla stic%20Was te% 20Book. Pdf - FICCI (2016) Indian plastic industry: challenges & opportunities. Retrieved from https://

www. slide share. net/ TSMG- Chemi cals/indian- plast ic- indus try- chall enges- oppor

tunit ies - Plastindia Foundation (2018) Report on The Indian Plastics Industry.Retrieved from

https:// plast india. org/ pdf/ Indian- Plast ics- Industry- Report- 2018-2. pdf